Byron Owen

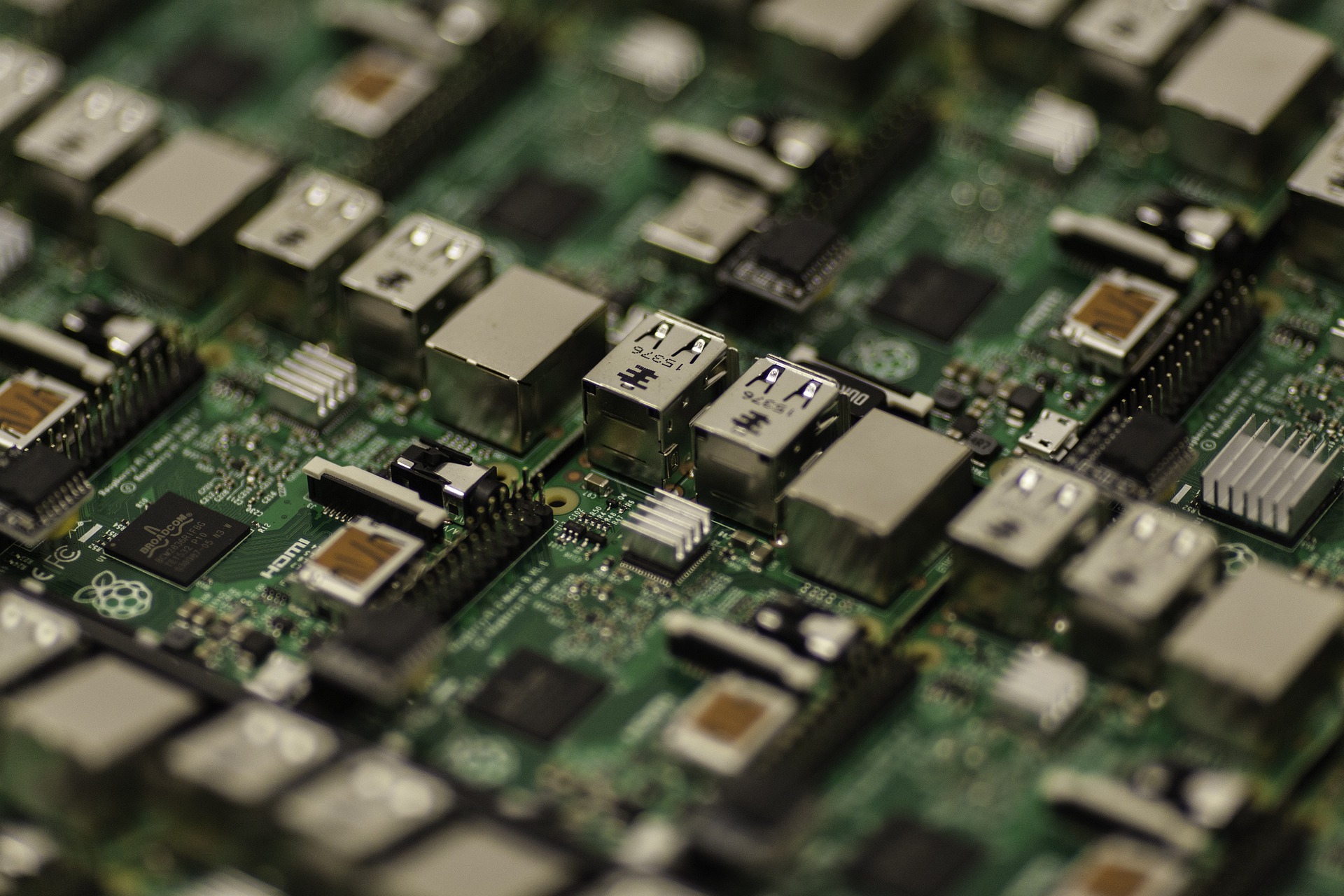

A single company in Taiwan, the Taiwan Semiconductor Manufacturing Company (TSMC), produces over 60% of the world’s microchips. Critically, over 90% of ten nanometer (nm) and smaller microchips across the globe have a TSMC stamp on them.[i] 10 nm chips serve as the backbone for the world’s cellular devices, computers, satellites, and other advanced electronics. There are only two other major producers of 10 nm chips, Samsung Electronics in South Korea and Intel in the United States. Any interruption to this critical production line would have significant impacts to almost every industry in the world. The COVID 19 pandemic highlighted the fragility of this supply chain in 2019. The production of semiconductors fell as TSMC adopted COVID19 mitigation procedures to protect their workforce. Global maritime trade networks collapsed as dock workers and other critical support personnel fell victim to the virus. This created a semi-conductor shortfall in the United States that negatively impacted the production of wired/wireless communications, automobiles, computers, medical equipment, and even home appliances.[ii]

The strategic requirement to increase domestic production of advanced microchips enjoys bipartisan support in the United States. The Trump administration coordinated with TSMC in 2020 to open a semi-conductor production facility in Arizona by 2024. President Biden signed the CHIPS and Science Act in 2022 and pledged 280 billion dollars to the domestic research and production of semi-conductors in the United States. The People’s Republic of China is also investing heavily in domestic production of semi-conductors. The Semiconductor Manufacturing International Corp. (SMIC) makes most of China’s advanced microchips, but they cannot currently produce any semi-conductors smaller than 14 nm. The PRC spent several billion dollars to upgrade TSMC’s fabrication plants in Shanghai and Nanjing since 2021 and aims to double the production of TSMC components in China soon.[iii]

The creation of a TSMC plant in the United States is critical to maintaining the American industrial base in a conflict. It is imperative that the U.S. does whatever it takes to ensure that TSMC completes this project and establishes a reliable domestic source for advanced semi-conductors. Congress ensured that sufficient money is available for this, but the government will have to be more proactive if it wants to secure this project’s success. In 2020 TSMC asked the Trump Administration to make up the cost difference between production in the U.S. versus Taiwan.[iv] In April 2023, TSMC asked for 8 billion dollars from the CHIPs Act and another 7 billion in grants from the Commerce Department. This is roughly a third of the projected cost of the factory in Arizona.[v]

A week ago, on July 20th, TSMC told the federal government that it will have to delay the opening of its plant in Arizona until 2025 because of a lack of skilled workers there. This echoes a complaint they lodged last year.[vi] Talent shortfalls are only part of the problem TSMC is facing in the United States, however. Licenses, permits, and other bureaucratic requirements are also delaying construction. This may be business as usual for American companies, but this is not what TSMC is used to. The timeline for building an advanced microchip facility in Asia averages two years. This was the case for the TSMC plants in Tainan, Taiwan; Nanjing, China; and their plants in Kaohsiung, Taiwan and Kumamoto, Japan are both on track to produce chips in 2024 after starting construction in 2022.[vii]

TSMC is sending Taiwanese technicians to Arizona to help accelerate construction, but they are clashing with the labor unions there who don’t like the competition for jobs. The influx of foreign workers is also driving down compensation for domestic laborers. For example, TSMC recently replaced 50 unionized electricians with 25 Taiwanese workers, after the Americans quit in protest of a salary cut. This put the semi-conductor company in the sites of pro-labor congressmen like Representative Ro Khanna from California who are understandably upset about how their constituents view this activity.[viii] The construction of the TSMC plant in Arizona will pit strategic requirements against domestic support. This puts our elected leaders in a precarious position, as they need to posture our nation for conflict, but must also appease their constituents to secure their positions in government. The American people may be aware of a rising threat in the Pacific but are probably more concerned about the rising price of bacon in the grocery store.

Domestic issues will generally impact voters more than international relations that may seem very distant to the American people. TSMC will probably have to figure out a way to accommodate the labor unions in Arizona, and the politicians that support them. The Biden administration can use funding from the CHIPS act to make it easier for TSMC to operate in Arizona by training American workers and offsetting the cost of using domestic labor. The government also needs to be more proactive in incentivizing skilled workers from around the country to move to Arizona. The demand for skilled labor in Arizona will continue exponentially in the future. Intel is investing 20 billion dollars to expand microchip production in their facility in Chandler, Arizona. This factory is 50 kilometers away from the TSMC facility and will compete for local talent.[ix] The government should look for solutions to this manpower shortfall outside of Arizona. Many U.S. cities and states offered remote workers economic incentives to move there during the COVID19 pandemic. Maine, for example, offered a $15,000 credit to help pay off student loans. Cities in Kansas, Maryland, Iowa, Michigan, Mississippi, and Oklahoma offered workers $10-15,000 cash bonuses to help them buy homes.[x] The federal government, TSMC, and the state of Arizona should consider similar means to convince skilled workers from around the country to move to Arizona.

The federal government and the state of Arizona should do whatever they can to ease some of the bureaucratic requirements, outside of safety controls, that are impeding progress on construction. The nation did something similar during World War II. The United States relaxed child labor laws during both World Wars, and employed over two million teenagers to help meet domestic production requirements. This is certainly not a necessary or advisable solution to our current problem but demonstrates that the United States has eased significant labor and construction policies in the past to help meet strategic requirements. At a minimum, Arizona should prioritize and accelerate any licensing or permit applications relating to the TSMC plant. This may require reinforcing the offices that process these requests with contractor support, which could be financially supported by the CHIPS Act.

This is not just a race against the Chinese. Apple is helping to subsidize the construction of the plant in Arizona but will soon require more advanced microchips than the facility is projected to manufacture. The current plan is to produce 5 nm chips once the factory opens in 2025. They may be able to increase the plant’s capabilities and manufacture 4 nm chips but this still may not be enough. The iPhone 15 Max, Apple’s newest iPhone that launches this October, utilizes 3 nm microchips.[xi] Smart phones will likely move to 2 nm microchips in the next year or two, which will make the plant in Arizona less relevant by the time it is fully online.[xii] The United States is in a race with the Chinese against the rapid pace of technological advancement.

There are no easy solutions to this problem. The Biden administration will have to balance the strategic requirements of bringing microchip production home vs domestic concerns about losing American jobs to foreign labor. These are considerations that the People’s Republic of China will not have to contend with as they expand their own production of domestic microchips. President Biden and the Governor of Arizona Katie Hobbs must work together to reduce bureaucratic obstacles and attract skilled labor to Arizona to prevent further delays at the TSMC plant in Phoenix. The United States must attack this problem from every possible direction if we hope to produce the right kinds of microchips domestically when we lose reliable access to our global supply lines.

This site is free for everyone to learn about information warfare, connect with mentors, and seek the high ground! Unfortunately operating the site is not free and your donations are appreciated to keep KTC up and running.

[i] https://www.economist.com/special-report/2023/03/06/taiwans-dominance-of-the-chip-industry-makes-it-more-important

[ii]https://www.mckinsey.com/~/media/McKinsey/Industries/Semiconductors/Our%20Insights/Coronavirus%20Implications%20for%20the%20semiconductor%20industry/Coronavirus-Implications-for-the-semiconductor-industry.pdf

[iii] https://www.scmp.com/tech/big-tech/article/3131823/why-has-tsmcs-nanjing-expansion-plan-stirred-hornets-nest-beijing-and

[iv] https://www.reuters.com/article/us-tsmc-agm-factory/tsmc-says-still-in-talks-about-subsidies-for-new-u-s-plant-idUSKBN23G0EY?feedType=RSS&feedName=technologyNews&utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+reuters%2FtechnologyNews+%28Reuters+Technology+News%29

[v] https://www.wsj.com/articles/tsmc-seeks-up-to-15-billion-from-u-s-for-chip-plants-but-objects-to-conditions-3bf6cfc1

[vi] https://www.wsj.com/articles/tsmc-delays-start-of-first-arizona-chip-factory-citing-worker-shortage-4a9344e5?mod=Searchresults_pos1&page=1

[vii] https://asia.nikkei.com/Business/Tech/Semiconductors/Construction-of-TSMC-s-U.S.-chip-plant-delayed-by-labor-crunch-COVID

[viii] https://reason.com/2023/07/25/taiwanese-company-demands-u-s-taxpayers-cover-the-higher-costs-of-making-semiconductors-in-arizona/

[ix] https://asia.nikkei.com/Business/Tech/Semiconductors/Construction-of-TSMC-s-U.S.-chip-plant-delayed-by-labor-crunch-COVID

[x] https://www.cbre.com/insights/articles/using-economic-incentives-to-attract-migrating-talent

[xi] https://9to5mac.com/2022/11/21/apple-chips-2/

[xii] https://www.macrumors.com/2023/04/25/tsmc-apple-3nm-chip-yield-struggles/

One response to “The Race for Domestic Semi-Conductor Production”

Good article – https://www.tomshardware.com/news/new-us-fabs-everything-we-know

Arizona is only one of the new Fabs being built. the 25% decline in US based SC production over the last 30 years will hopefully begin to turn around over the next few year. C-19 was only a taste at would “could be”. Looks like US Based Corps learned from it.